Bioscrubbing

What is it?

Bioscrubbing combines wet gas scrubbing (absorption) and biodegradation; the scrubbing water contains a population of microorganisms suitable to oxidise noxious gaseous compounds. The microorganisms are suspended in water.

Hence, the conditions to use bioscrubbers are:

Bioscrubbers are frequently inoculated with activated sludge, e.g. from a biological waste water treatment plant. Depending on the composition of the waste gas, the performance of the bioscrubber will only attain the desired level after some weeks of adaptation.

Inoculation with cultures prepared in fermenters is particularly applied to contaminants that contain sulphur (mercaptans, hydrogen sulphide, dimethyl sulphide, etc.) or chlorine (chlorinated methanes or ethanes).

Hence, the conditions to use bioscrubbers are:

- the existence of the possibility to wash out the waste gas constituents;

- the washed-out constituents must be biodegradable under aerobic conditions.

Bioscrubbers are frequently inoculated with activated sludge, e.g. from a biological waste water treatment plant. Depending on the composition of the waste gas, the performance of the bioscrubber will only attain the desired level after some weeks of adaptation.

Inoculation with cultures prepared in fermenters is particularly applied to contaminants that contain sulphur (mercaptans, hydrogen sulphide, dimethyl sulphide, etc.) or chlorine (chlorinated methanes or ethanes).

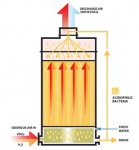

- Figure 1. Scheme of a bioscrubber (1)

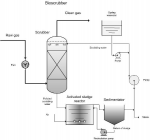

- Figure 2. Scheme of a bioscrubber (2)

Design, maintenance and efficiency

The bioscrubber should be designed in such a way that the residence time of the gases is around one second. Depending on the solubility of the compounds, this may be slightly more or less. The bioscrubber requires a special open packing and special spray nozzles to prevent clogging due to the biological sludge. A hydraulic residence time of the scrubbing water of between 20 and 40 days gives the best results.

Applicability

Bioscrubbing is well-suited to low concentrations of pollutants that are easily soluble in water; it is well-suited to the abatement of alcohols, aldehydes and ketones, carboxylic acids and their esters, phenols, heterocyclic sulphur and nitrogen compounds, mercaptans, amines, chlorophenols, hydrogen sulphide, naphthalene, sulphides and ammonia.

It is not suited for aliphatic hydrocarbons, aromatic hydrocarbons, ethers and halogenated hydrocarbons.

Application of bioscrubbers for odour removal can be found in:

Table 1 shows application limits and restrictions associated with bioscrubbing (adapted from EIPPCB, 2016, Table 3.185).

Table 1. Application limits and restrictions associated with bioscrubbing.

It is not suited for aliphatic hydrocarbons, aromatic hydrocarbons, ethers and halogenated hydrocarbons.

Application of bioscrubbers for odour removal can be found in:

- Cigarette industry: Odour concentration is reduced by approximately 5000 ouE/m3 to 200 – 300 ouE/m3

- Wastewater treatment plants

- Production of enzymes

- Production of aromas

- Rubber industry

- Production of polymers

- Processing of paint residues

Table 1 shows application limits and restrictions associated with bioscrubbing (adapted from EIPPCB, 2016, Table 3.185).

Table 1. Application limits and restrictions associated with bioscrubbing.

| Issue | Limits/ Restrictions |

|---|---|

| Gas flow (Nm3/h) | 1000-3000 Nm3/h per m2 of column surface |

| Temperature (°C) | 15-40 30-35 (optimum) |

| Pressure (MPa) | Atmospheric |

| Pressure drop (mbar) | 2-3 |

| Sludge concentration | Maximum 15 g/l dry matter |

| Odour concentration (ouE/m3) | >10000 |