Improving the Emission Dispersion Capability

The impact caused by an odour source on its surroundings is not only due to the emitted odour concentration and of the gas flow rate (the product of the odour concentration and of the air flow rate is called “Odour Emission Rate” – OER), but also of how the emitted air flow is dispersed into the atmosphere before it reaches a certain receptor.

For this reason, an alternative effective strategy to reduce odour impacts is to improve the dispersion capability of an odour source. This can be achieved basically (but not exclusively) with the following technical interventions.

For this reason, an alternative effective strategy to reduce odour impacts is to improve the dispersion capability of an odour source. This can be achieved basically (but not exclusively) with the following technical interventions.

- For non-conveyed emissions, by conveying emissions into a stack (Zanetti et al., 2010). One typical example where this solution is applicable is represented by sheds without forced ventilation, where the emissions occur by diffusion through the openings (i.e. doors and windows). In such cases, if ventilation is forced through one (or more) stacks by fans (Figure 1), dispersion can be greatly improved, thereby reducing the odour impact significantly.

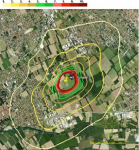

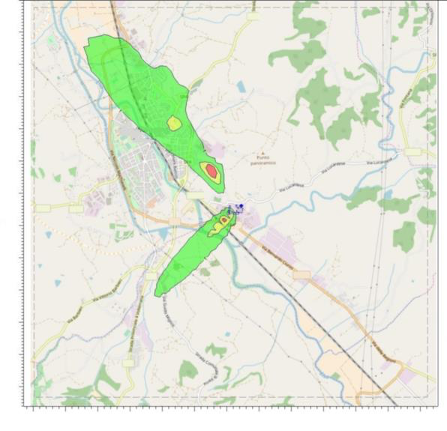

- Verticalization of horizontal emissions . In industrial applications, there are a lot of situations where emissions are horizontal, or where vertical stacks are equipped with “raincaps” (Figure 2). Despite the undeniable advantages of preventing the entrance of rainwater, and in some cases of facilitating the deposition of emitted dust in proximity of the source, such technical features inhibit the vertical component of the emission outlet velocity, thus worsening the dispersion capability significantly. For this reason, technical interventions aiming to “verticalize” such emissions, which increase the so called “plume rise” effect, can produce a significant benefit in terms of odour dispersion, thus resulting in a reduction of the odour impact. Figures 3 and 4 show two odour dispersion maps comparing the odour impact related to a plant with horizontal emissions (Figure 3) with the odour impact produced if the same emissions are vertical instead of horizontal (Figure 4): indeed, a significant reduction of the odour impact is obtained without reducing the emitted odour concentration.

- Figure 1. Example of horizontal emissions

- Figure 2. Example of and stack with raincap

- Figure 3. Plant odour impact with horizontal emissions

- Figure 4. Plant odour impact with verticalised emissions

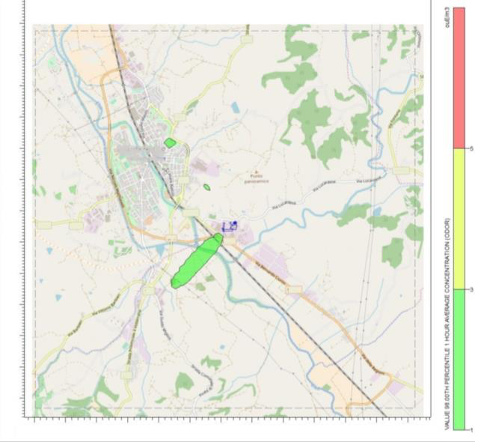

- Increasing the stack height . Another effective way of enhancing the dispersion capability of an emission, is increasing the height of the release point. In the case of point sources (through a stack), this means increasing the stack height. This solution is particularly effective if the emission point is raised at heights of about 50 m, for which the dispersion capability of the stack improve significantly. Figure 5 shows the odour impact related to a stack with a height of 27m with the odour impact produced by the same stack at a height of 50m (Figure 6): indeed, a significant reduction of the odour impact is obtained without reducing the emitted odour concentration.

Figure 5. Odour impact related to the emission from a stack with a height of 27m

Figure 6. Odour impact related to the emission from a stack with a height of 50m

These solutions, despite not necessarily banal, have the advantage of being generally more economic than others, involving the realization of a new abatement system. Indeed, the modification of a plant design for the improvement of the dispersion capability of an odour source usually involves (sometimes high) investment costs, but after that it has no operational costs. And in many cases, they can produce very high benefits in terms of odour impact reduction. This type of solution is particularly indicated where the waste gas stream is hardly treated with the common technologies, or where abatement systems are already applied, and their abatement efficiency is not sufficient to meet odour impact criteria.

Another positive aspect is that the effect of such solutions can be preventively be verified before their implementation by applying dispersion modelling.

Another positive aspect is that the effect of such solutions can be preventively be verified before their implementation by applying dispersion modelling.